Homemaster-MiniPLC

Product description

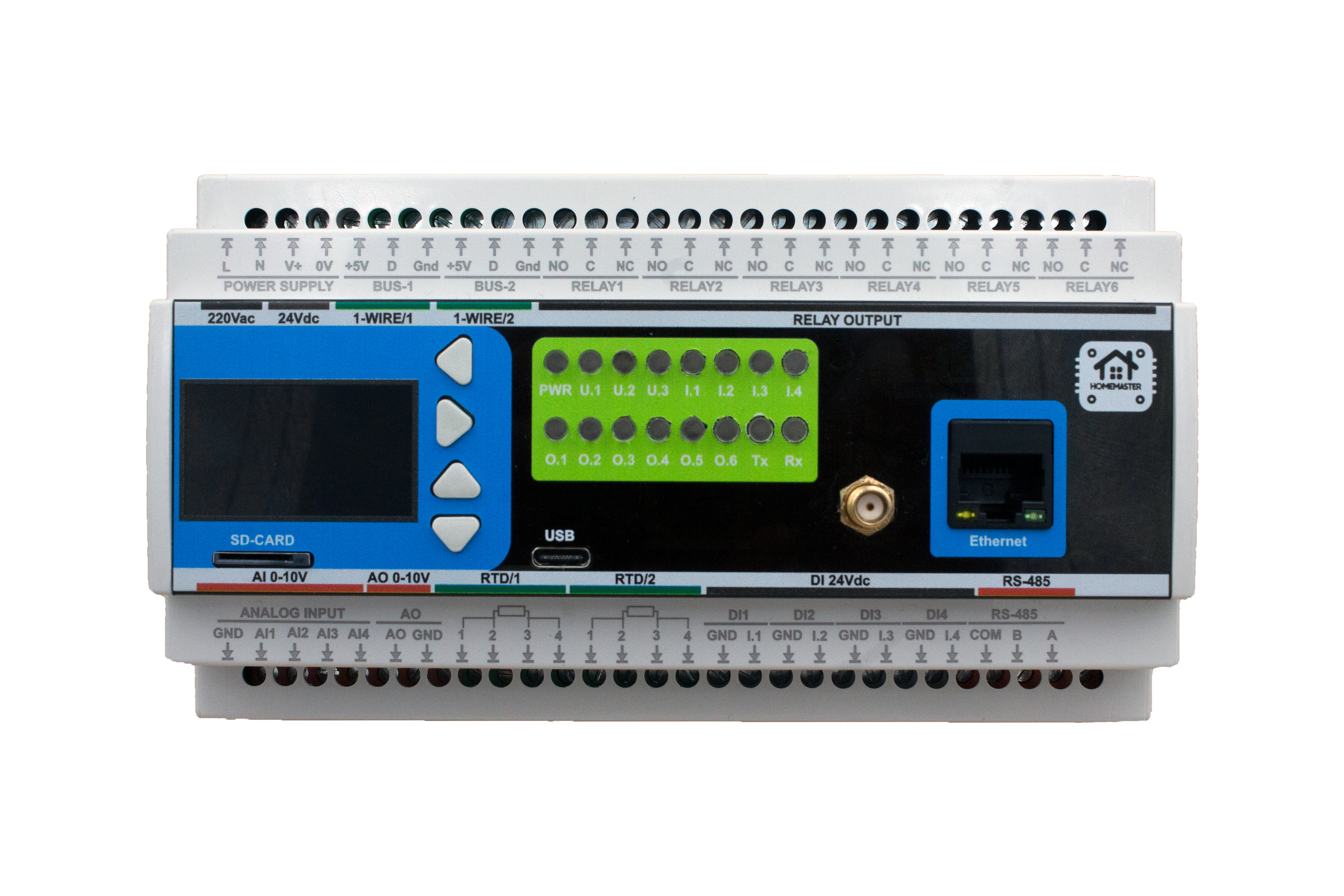

The HOMAMASTER MiniPLC is a powerful and compact automation controller designed for advanced smart home applications. Built around the ESP32-WROOM-32U

Maker: https://www.home-master.eu/

Product page: https://www.home-master.eu/shop/esp32-miniplc-55

Key Features

24V Digital Inputs – 4 industrial-grade inputs for dry contacts.

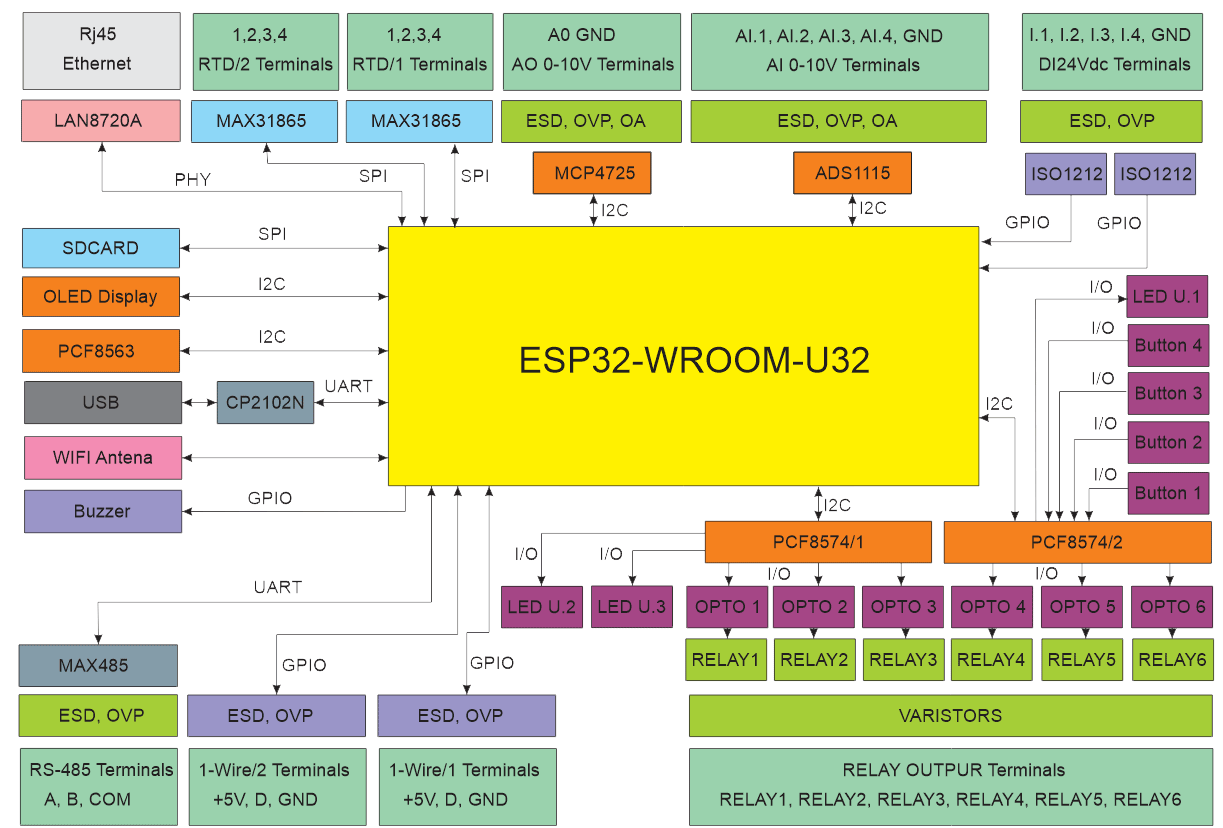

Relay Outputs – 6 relays controlled via I²C expanders for switching AC/DC loads.

Analog Inputs – 4 high-resolution 16-bit channels (ADS1115) for monitoring 0–10V signals.

Analog Output (0–10V) – 1 DAC output (MCP4725) for generating analog control signals.

Temperature Sensors – Supports 2xRTD (MAX31865) sensors.

Two 1-Wire.

User Interface – 4 front-panel buttons and configurable LEDs for local interaction.

OLED Display – 128x64 screen for displaying data and interaction.

RTC with Backup – PCF8563 real-time clock with Home Assistant synchronization.

I²C Expanders – PCF8574 chips expand digital I/O for more flexible device control.

Modbus RTU – UART-based support for extension modules.

Networking

Wi-Fi Connectivity – Integrated Wi-Fi for wireless access and Home Assistant integration.

Ethernet Support – Optional LAN8720 PHY via RMII interface for reliable wired networking.

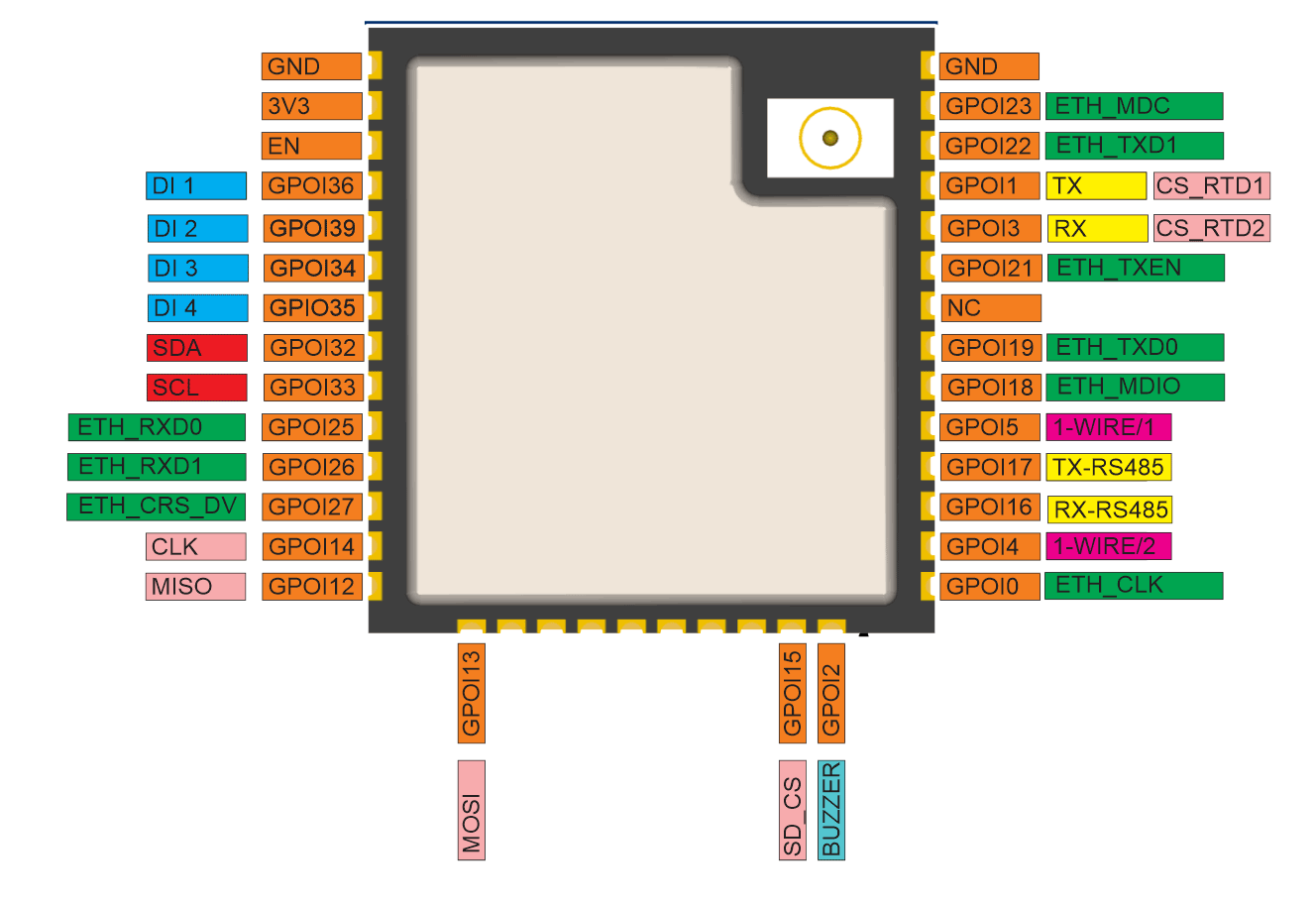

Pinout

MiniPLC Functional Block Diagram

Programming

The MiniPLC comes with ESPHome pre-installed and can be programmed via:

Wi-Fi: Use the ESPHome Dashboard to upload the configuration.

USB Type-C: Use the ESPHome Dashboard to upload the configuration.

Integrated Webserver: Access the MiniPLC's IP address, upload the configuration via the built-in web UI.

Bus system configuration

I2C

| PIN | |

|---|---|

| SDA | GPIO32 |

| SCL | GPIO33 |

I2C addresses

| address | |

|---|---|

| pcf8574/2 | 0x38 |

| pcf8574/1 | 0x39 |

| ads1115 | 0x48 |

| SH1106 128x64 | 0x3C |

| pcf8563 | 0x51 |

SPI

| PIN | |

|---|---|

| MISO | GPIO12 |

| MOSI | GPIO13 |

| CLK | GPIO14 |

SPI_CS pins

| PIN | |

|---|---|

| max31865 RTD1 | GPIO01 |

| max31865 RTD1 | GPIO03 |

| SDCARD | GPIO15 |

Basic Config

# ESPHome configuration for MiniPLC

# This file configures an ESP32-based automation controller with:

# - Modbus RTU over UART

# - 1-Wire sensors

# - I2C PCF8574 expanders

# - I2C PCF8563 RTC

# - SPI-based MAX31865 temperature sensors

# - ADC inputs via ADS1115

# - DAC input MCP4725

# - OLED display over I2C

# - Ethernet

# - Web and API access

# - Multiple GPIOs managed via PCF8574 expanders

esphome:

name: miniplc # Internal device name used by ESPHome

friendly_name: MiniPLC # Friendly name shown in Home Assistant

esp32:

board: esp32dev # ESP32 development board type

framework:

type: arduino # Use Arduino framework (vs ESP-IDF)

# Enable logging via UART for debugging

logger:

# Wi-Fi configuration with manual static IP

wifi:

ssid: !secret wifi_ssid

password: !secret wifi_password

# Enable fallback web portal if Wi-Fi fails

captive_portal:

# ------------------------------------------------------------------------------

# Ethernet Configuration (optional, currently commented out)

# This section allows using a LAN8720 PHY with ESP32 over RMII interface.

# It can be used instead of Wi-Fi by uncommenting and configuring.

# See: https://esphome.io/components/ethernet.html

# ------------------------------------------------------------------------------

# ethernet:

# type: LAN8720 # Ethernet PHY chip type

# mdc_pin: GPIO23 # Management Data Clock

# mdio_pin: GPIO18 # Management Data IO

# clk_mode: GPIO0_OUT # Use GPIO0 for 50 MHz external clock

# phy_addr: 1 # PHY address (check schematic/config)

# Simple built-in web server for basic status and diagnostics

web_server:

port: 80

version: 3

# UART used for Modbus RTU communication

uart:

tx_pin: 17 # Transmit (TX) pin to RS485 driver (DI pin on MAX485)

rx_pin: 16 # Receive (RX) pin from RS485 driver (RO pin on MAX485)

baud_rate: 19200 # Must match the slave device's configuration.

# 19200 is a common industrial standard offering a good balance between speed and reliability.

# Use lower (e.g., 9600) for longer cables or noisy environments; higher (e.g., 115200) for faster data if wiring conditions allow.

id: mod_uart # ID to reference this UART bus in the modbus block

modbus:

send_wait_time: 200ms # Minimum time between requests (to prevent overloading devices)

uart_id: mod_uart # Uses the UART interface defined above

id: mod_bus # ID of the Modbus master instance

# OneWire bus for temperature sensors (two separate GPIOs)

one_wire:

- platform: gpio

pin: GPIO05

id: hub_1

- platform: gpio

pin: GPIO04

id: hub_2

# I2C configuration

i2c:

- id: bus_a

sda: 32 # GPIO32 is used for the I²C SDA (data) line

scl: 33 # GPIO33 is used for the I²C SCL (clock) line

frequency: 400kHz # I²C bus speed set to 400kHz (Fast Mode)

# This higher frequency is required for correct communication with the SH1106 OLED display.

# Lower frequencies (like the default 100kHz) may cause issues such as slow updates or no display at all.

timeout: 1s # Maximum time to wait for I²C communication before considering it failed

scan: true # Enables automatic scanning for connected I²C devices during boot

# Real-Time Clock (PCF8563) and Home Assistant time sync

# This ensures that the ESP32 and Home Assistant remain synchronized and allows

# for time-based automations, scheduled events

time:

- platform: pcf8563

id: pcf8563_time

address: 0x51 # I2C address of the PCF8563 RTC module

- platform: homeassistant

on_time_sync:

then:

pcf8563.write_time: # Update RTC with Home Assistant time

# I/O Expanders (PCF8574) on I2C

# In this configuration: `pcf8574_hub_a` and `pcf8574_hub_b` are used for handling buttons, LEDs, and relays.

pcf8574:

- id: 'pcf8574_hub_a'

address: 0x38 # I2C address for the first PCF8574 expander

pcf8575: false # Set to false as we're using the PCF8574 (not the PCF8575)

- id: 'pcf8574_hub_b'

address: 0x39 # I2C address for the second PCF8574 expander

pcf8575: false # Set to false as we're using the PCF8574 (not the PCF8575)

# ADC via ADS1115 (4 channels, 16-bit resolution)

ads1115:

- address: 0x48

# SPI configuration for MAX31865 RTD sensors

spi:

miso_pin: GPIO12

mosi_pin: GPIO13

clk_pin: GPIO14

# Text Sensor to Format Current Time for Display

# ------------------------------------------------------------------------------

# This text sensor is used to format the current time obtained from the PCF8563 RTC

# module and send it to Home Assistant.

text_sensor:

- platform: template

name: "Current time"

id: current_time

lambda: |-

char str[17];

time_t currTime = id(pcf8563_time).now().timestamp;

strftime(str, sizeof(str), "%Y-%m-%d %H:%M", localtime(&currTime));

return { str };

update_interval: 60s

# Fonts for OLED display (loaded via Google Fonts)

font:

- file: "gfonts://Roboto"

id: font1

size: 8

- file: "gfonts://Roboto"

id: font2

size: 48

- file: "gfonts://Roboto"

id: font3

size: 14

# OLED display via I2C (SH1106 128x64)

# The OLED display (SH1106 128x64) is connected via I2C to provide a visual output

# of key information.

#

# The information displayed includes:

# - A fixed title ("HOMEMASTER") centered at the top.

# - The current time from the PCF8563 RTC, formatted as "HH:MM".

display:

- platform: ssd1306_i2c

model: "SH1106 128x64" # Model of the OLED display

address: 0x3C # I2C address of the display

rotation: 180 # Rotate the display 180 degrees for correct orientation

contrast: 100% # Set maximum contrast for better readability

id: oled_display # Unique ID for the display

update_interval: 1s # Update display every second

lambda: |-

# Display the title centered at the top of the screen

it.printf(64, 0, id(font1), TextAlign::TOP_CENTER, "HOMEMASTER");

# Display the current time from the RTC, formatted as HH:MM

it.strftime(0, 60, id(font2), TextAlign::BASELINE_LEFT, "%H:%M", id(pcf8563_time).now());

# Binary inputs: 4 local GPIOs and 4 buttons via PCF8574

binary_sensor:

# Digital Inputs for 24V DC sourcing devices (DI)

- platform: gpio

pin: { number: GPIO36 } # DI #1

name: "DI #1"

- platform: gpio

pin: { number: GPIO39 } # DI #2

name: "DI #2"

- platform: gpio

pin: { number: GPIO34 } # DI #3

name: "DI #3"

- platform: gpio

pin: { number: GPIO35 } # DI #4

name: "DI #4"

# Front Panel Buttons connected to I/O expander (PCF8574)

- platform: gpio

name: "Button #1"

pin: { pcf8574: pcf8574_hub_a, number: 0, inverted: true } # MiniPLC front panel Button 1 (inverted logic)

- platform: gpio

name: "Button #2"

pin: { pcf8574: pcf8574_hub_a, number: 1, inverted: true } # MiniPLC front panel Button 2 (inverted logic)

- platform: gpio

name: "Button #3"

pin: { pcf8574: pcf8574_hub_a, number: 2, inverted: true } # MiniPLC front panel Button 3 (inverted logic)

- platform: gpio

name: "Button #4"

pin: { pcf8574: pcf8574_hub_a, number: 3, inverted: true } # MiniPLC front panel Button 4 (inverted logic)

# Switch Relays and Buzzer Configuration

# ------------------------------------------------------------------------------

# This section configures the relays (output switches) and buzzer connected to the I/O

# expanders (PCF8574) and other GPIO pins on the ESP32.

#

# **Switch Relays**:

# - Each relay is configured with a specific name and a GPIO pin on the expander to control its state:

# - **Relay #1**: Connected to `pcf8574_hub_b`, pin number 2 (inverted logic: LOW to activate).

# - **Relay #2**: Connected to `pcf8574_hub_b`, pin number 1 (inverted logic: LOW to activate).

# - **Relay #3**: Connected to `pcf8574_hub_b`, pin number 0 (inverted logic: LOW to activate).

# - **Relay #4**: Connected to `pcf8574_hub_a`, pin number 6 (inverted logic: LOW to activate).

# - **Relay #5**: Connected to `pcf8574_hub_a`, pin number 5 (inverted logic: LOW to activate).

# - **Relay #6**: Connected to `pcf8574_hub_a`, pin number 4 (inverted logic: LOW to activate).

# **LEDs (User-configurable)**:

# - **LED #2**: Connected to `pcf8574_hub_b`, pin number 3 (inverted logic: LOW to turn on).

# - **LED #3**: Connected to `pcf8574_hub_b`, pin number 4 (inverted logic: LOW to turn on).

# - The LEDs are **not** tied to relay status, but are instead **user-configurable** and can be used for

# any purpose that the user requires, such as indicators, feedback lights, or status lamps for other system conditions.

# - The user can assign logic for turning the LEDs on or off based on specific requirements, such as device status or manual control.

# - The LEDs are connected to the I/O expander and can be turned on or off by controlling their respective GPIO pins.

# **Buzzer**:

# - The buzzer provides an audible notification or alarm when triggered.

# - The buzzer is connected to **GPIO02** through an **LEDC output** (Pulse Width Modulation - PWM).

# - The buzzer is controlled using a **template switch** to turn it on or off.

# - When turned on, the buzzer emits a tone at a frequency of **2441Hz** at **75% volume**.

# - The buzzer is used to signal important events or alarms in the system, such as errors, notifications, or alerts.

# **Switches (Relays and LEDs)**:

# The switches and relays are controlled through the **GPIO pins** and the **I/O expander**:

switch:

# Relay switches for controlling external devices

- platform: gpio

name: "RELAY #1"

pin: { pcf8574: pcf8574_hub_b, number: 2, mode: { output: true }, inverted: true } # Inverted logic (LOW to activate)

- platform: gpio

name: "RELAY #2"

pin: { pcf8574: pcf8574_hub_b, number: 1, mode: { output: true }, inverted: true } # Inverted logic (LOW to activate)

- platform: gpio

name: "RELAY #3"

pin: { pcf8574: pcf8574_hub_b, number: 0, mode: { output: true }, inverted: true } # Inverted logic (LOW to activate)

- platform: gpio

name: "RELAY #4"

pin: { pcf8574: pcf8574_hub_a, number: 6, mode: { output: true }, inverted: true } # Inverted logic (LOW to activate)

- platform: gpio

name: "RELAY #5"

pin: { pcf8574: pcf8574_hub_a, number: 5, mode: { output: true }, inverted: true } # Inverted logic (LOW to activate)

- platform: gpio

name: "RELAY #6"

pin: { pcf8574: pcf8574_hub_a, number: 4, mode: { output: true }, inverted: true } # Inverted logic (LOW to activate)

# User-configurable LEDs (not tied to relay status)

- platform: gpio

name: "LED #2" # MiniPLC front panel LED U.2.

pin: { pcf8574: pcf8574_hub_b, number: 3, mode: { output: true }, inverted: true } # Inverted logic (LOW to turn on)

- platform: gpio

name: "LED #3" # MiniPLC front panel LED U.3.

pin: { pcf8574: pcf8574_hub_b, number: 4, mode: { output: true }, inverted: true } # Inverted logic (LOW to turn on)

# Buzzer control (using LEDC output)

- platform: template

name: "Switch buzzer"

optimistic: true

turn_on_action:

- output.turn_on: buzzer_output # Turn on buzzer

- output.ledc.set_frequency: { id: buzzer_output, frequency: "2441Hz" } # Set buzzer frequency (2441Hz)

- output.set_level: { id: buzzer_output, level: "75%" } # Set buzzer volume to 75%

turn_off_action:

- output.turn_off: buzzer_output # Turn off buzzer

# 0–10V fan output using DAC

# In this section, the DAC is not used to control fan speed. Instead, it is used

# for generating a 0-10V analog voltage signal. This output can be utilized for

# any application requiring a 0-10V analog signal, such as controlling motors,

# actuators, or other industrial devices.

output:

- platform: ledc

pin: GPIO02 # GPIO connected to buzzer

id: buzzer_output # ID for referencing in switch actions

# This PWM output is used to drive the buzzer with a specific tone (frequency)

# and loudness (duty cycle). It can be turned on/off or modulated in software.

# DAC Configuration for generating 0-10V analog output

# ------------------------------------------------------------------------------

# The MCP4725 DAC is used to generate a 0-10V output, which can be used

# for various applications requiring an analog voltage control signal.

# Examples: voltage-controlled devices, industrial control systems, etc.

# DAC output for analog control

- platform: mcp4725

id: dac_output # ID for the DAC output

fan:

- platform: speed

output: dac_output # Using DAC output to generate a 0-10V analog signal

name: "DAC 0-10V Output" # Descriptive name for the 0-10V analog output

# This section demonstrates the use of the DAC for generating a 0-10V signal,

# which is sent to a device that requires an analog voltage input, such as a

# motor or actuator, rather than controlling fan speed directly.

# Temperature sensors

sensor:

# --------------------------------------------------------------------------

# 1-Wire (Dallas) Temperature Sensors

# --------------------------------------------------------------------------

# These sensors are connected via the 1-Wire protocol using dedicated GPIOs.

# Each sensor is identified by its unique 64-bit address and connected to a specific bus.

# Ideal for simple and reliable ambient or surface temperature measurements.

- platform: dallas_temp

one_wire_id: hub_1 # Connected to GPIO5

address: 0x6f7c86e908646128 # Unique sensor ID

name: "1-WIRE Dallas temperature BUS1"

update_interval: 60s # Update every 60 seconds

- platform: dallas_temp

one_wire_id: hub_2 # Connected to GPIO4

address: 0xbc3c01d075cb5128 # Unique sensor ID

name: "1-WIRE Dallas temperature BUS2"

update_interval: 60s

# --------------------------------------------------------------------------

# SPI-based RTD Temperature Sensors using MAX31865

# --------------------------------------------------------------------------

# These sensors are connected over the SPI bus and are designed for high-accuracy

# temperature readings using PT100/PT1000 RTDs.

# MAX31865 performs resistance-to-temperature conversion internally.

# Configuration includes reference resistance and nominal RTD resistance.

- platform: max31865

name: "MAX 31856 Temperature 1"

cs_pin: GPIO1 # Chip-select pin for sensor 1

reference_resistance: 400 Ω # External reference resistor value

rtd_nominal_resistance: 100 Ω # PT100 RTD (100 ohm at 0°C)

update_interval: 60s

- platform: max31865

name: "MAX 31856 Temperature 2"

cs_pin: GPIO3 # Chip-select pin for sensor 2

reference_resistance: 4000 Ω # External reference resistor

rtd_nominal_resistance: 1000 Ω # PT1000 RTD (1000 ohm at 0°C)

update_interval: 60s

# ------------------------------------------------------------------------------

# Analog Inputs via ADS1115 (External 16-bit ADC over I2C)

# ------------------------------------------------------------------------------

# The ADS1115 is a precision 16-bit ADC connected over I2C.

# It provides four single-ended analog input channels (A0–A3).

# These are used to measure external analog signals (e.g., 0–10V sensors via voltage divider).

# Each input is configured with:

# - Gain: Defines input voltage range (e.g., 6.144V for full scale).

# - Multiplexer: Selects input channel.

# - Filters: Optional scaling or calibration (here multiplying by 3).

- platform: ads1115

multiplexer: 'A0_GND' # Analog channel A0 referenced to GND

gain: 6.144 # ±6.144V range for full-scale measurement

name: "ADC AI4" # Analog Input 4

update_interval: 60s

filters: [ { multiply: 3 } ] # Scale raw ADC value if needed (e.g., voltage divider)

- platform: ads1115

multiplexer: 'A1_GND' # Analog channel A1 referenced to GND

gain: 6.144

name: "ADC AI3" # Analog Input 3

update_interval: 60s

filters: [ { multiply: 3 } ]

- platform: ads1115

multiplexer: 'A2_GND' # Analog channel A2 referenced to GND

gain: 6.144

name: "ADC AI2" # Analog Input 2

update_interval: 60s

filters: [ { multiply: 3 } ]

- platform: ads1115

multiplexer: 'A3_GND' # Analog channel A3 referenced to GND

gain: 6.144

name: "ADC AI1" # Analog Input 1

update_interval: 60s

filters: [ { multiply: 3 } ]

# ------------------------------------------------------------------------------

# Status LED Configuration

# ------------------------------------------------------------------------------

# This LED is used to indicate the device's operational status (e.g. booting, errors).

# It is controlled by ESPHome automatically unless manually overridden.

# In this setup, the LED is connected via an I/O expander (PCF8574), not directly to an ESP32 GPIO.

# It helps monitor system health visually on the MiniPLC front panel LED U.1.

status_led:

pin:

pcf8574: pcf8574_hub_a # I/O expander used instead of native GPIO

number: 7 # Pin number on PCF8574 hub A

mode: { output: true } # Configured as output

inverted: false # LED logic: HIGH = ON, LOW = OFF